Image 1 of 5

Image 1 of 5

Image 2 of 5

Image 2 of 5

Image 3 of 5

Image 3 of 5

Image 4 of 5

Image 4 of 5

Image 5 of 5

Image 5 of 5

Guatemala | Blue Ayarza - Natural

Roaster’s tasting notes: creamy toffee, strawberry, vanilla

This natural top lot was processed in a neighbouring farm land to Ayarza cherry mill in Santa Rosa. In Guatemala, coffee is traditionally processed individually by smallholder farmers, making it difficult to manage and guarantee quality form lot to lot. The team in Ayarza works with numerous farmers in the region, paying a premium for ripe cherry and processing it centrally to maintain strict standards throughout. To find a hot, sunny and flat space to dry the coffee, they use space on a farm higher up the mountain.

Linda visited the cherry mill in May 2025 to see the processes, innovative methods being used to reduce the carbon footprint, and the reinvestment into the local community. During the visit, she saw firsthand the composting methods used on the discarded cherry pulp, capturing heat which was then reused in coffee processing.

The coffee cherries start in a depth of 4-6 inches and are turned during the day. Over the first few days the coffee turns from red or yellow to a deep purple then black. They finish the drying in a mechanical drier for a few hours. This avoids a common challenge in sun dried naturals where the coffee re absorbs humidity in the morning then dries during the day and repeats until there are a few days of strong sun. We also find that the acidity is improved when finished in a drier (and it reduces the risk of the coffee getting caught in an untimely rain shower!)

PRODUCER: Small Holder Farmers

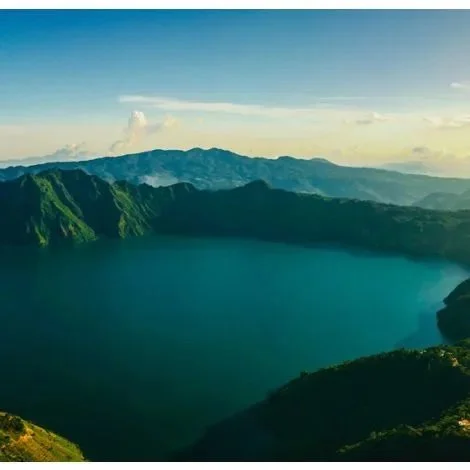

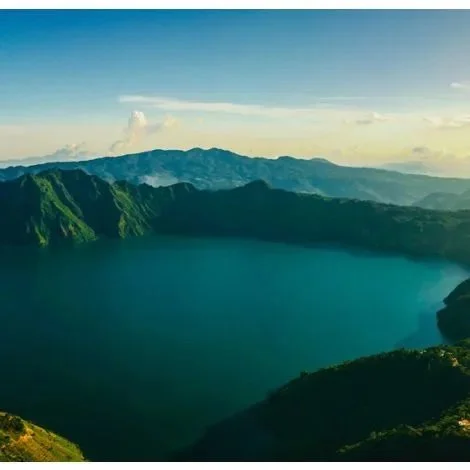

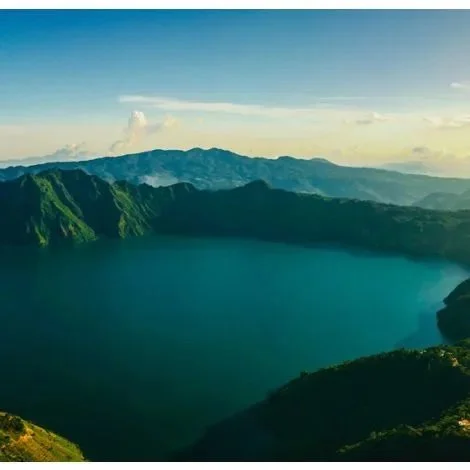

SUBREGION: Lake Ayarza, Santa Rosa

PROCESS: Natural

ALTITUDE: 1400-2000 masl

VARIETAL: Bourbon, Catuai, Pache, Anacafe14, San Ramon

Roaster’s tasting notes: creamy toffee, strawberry, vanilla

This natural top lot was processed in a neighbouring farm land to Ayarza cherry mill in Santa Rosa. In Guatemala, coffee is traditionally processed individually by smallholder farmers, making it difficult to manage and guarantee quality form lot to lot. The team in Ayarza works with numerous farmers in the region, paying a premium for ripe cherry and processing it centrally to maintain strict standards throughout. To find a hot, sunny and flat space to dry the coffee, they use space on a farm higher up the mountain.

Linda visited the cherry mill in May 2025 to see the processes, innovative methods being used to reduce the carbon footprint, and the reinvestment into the local community. During the visit, she saw firsthand the composting methods used on the discarded cherry pulp, capturing heat which was then reused in coffee processing.

The coffee cherries start in a depth of 4-6 inches and are turned during the day. Over the first few days the coffee turns from red or yellow to a deep purple then black. They finish the drying in a mechanical drier for a few hours. This avoids a common challenge in sun dried naturals where the coffee re absorbs humidity in the morning then dries during the day and repeats until there are a few days of strong sun. We also find that the acidity is improved when finished in a drier (and it reduces the risk of the coffee getting caught in an untimely rain shower!)

PRODUCER: Small Holder Farmers

SUBREGION: Lake Ayarza, Santa Rosa

PROCESS: Natural

ALTITUDE: 1400-2000 masl

VARIETAL: Bourbon, Catuai, Pache, Anacafe14, San Ramon